Next Generation of Hard Hats

Collaborative Sponsored Project > Industrial Design > 10 Week Internship

SCAD collaborated with Clayco to research and develop concepts for new construction hard hats.

The general design of the hard hat had not developed much over the past 60 years and Clayco’s vision for this project was to patent and manufacture a “Hard Hat of the Future.”

Our mission was to design a sustainable and durable hard hat to make the lives of construction workers more safe and comfortable.

My Role: Event Manager, Design Researcher, Lead 3D Modeler and Render Development, Client Pitch Presenter, Industrial Designer and Process Book Team

Process

Gathering Insights

Our team conducted secondary and primary research.

Through methodical and investigative strategies we studied brand, trends, fits and accessories, user expectations, behaviors, needs and motivations.

Primary Research

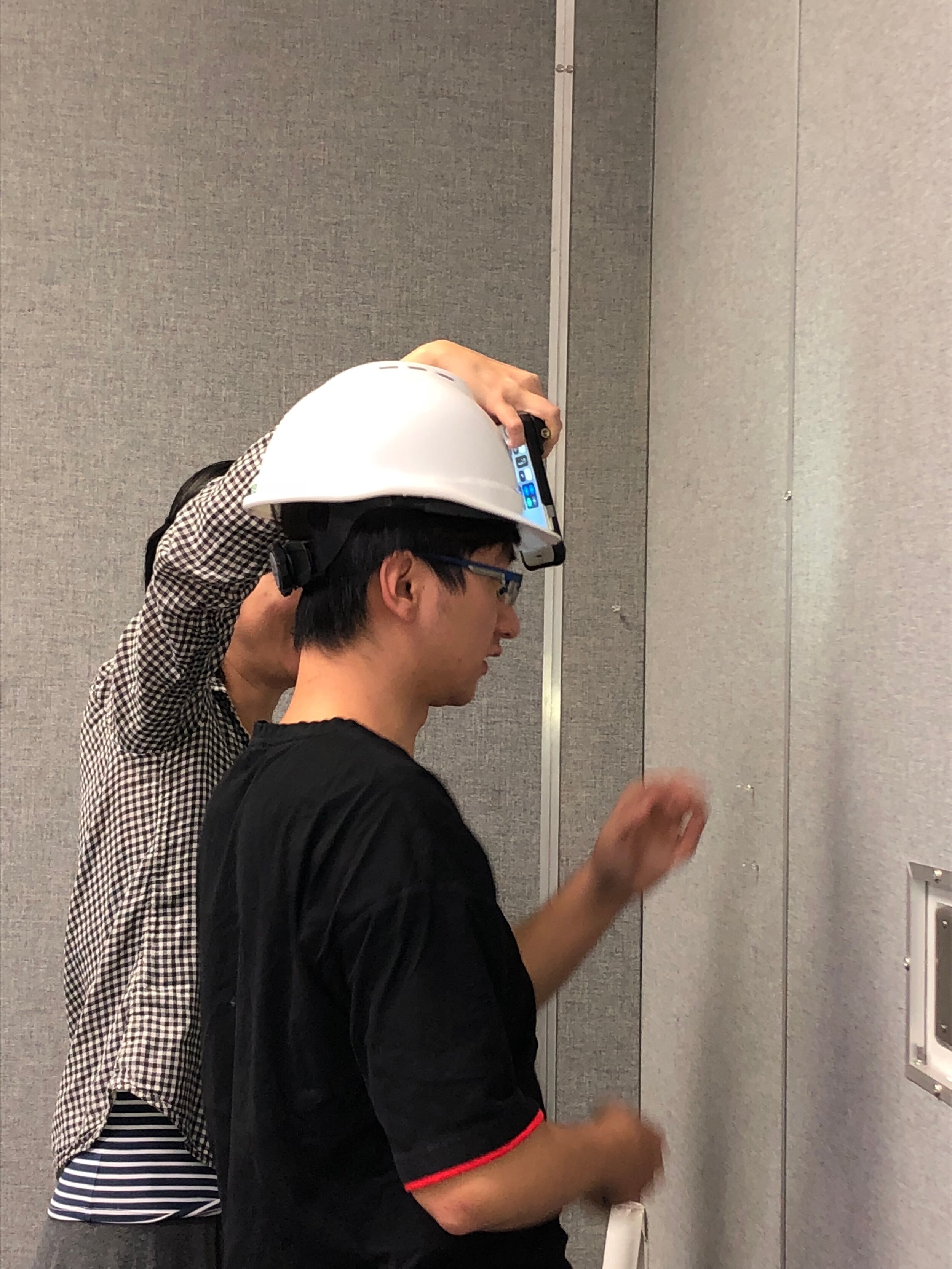

We visited a Clayco work site at the SCAD Atlanta campus to conduct on site interviews, set up a cultural probe, product demonstrations and to make observations. We got a chance to really interact and understand our end user and to identify the different types of users for hard hats. This ultimately helped our team to come to the decision of creating 3 separate hard hat deliverable to cater to the needs of each type of of user.

During our visit we got the chance to observe Clayco employees as they went about their usual day on the job. We got to interact with them, understand their values, pain points and preferences.

With the cultural probe we were able to gain insights from a wide range of employees. We also had interactive sessions where the workers demonstrated the different ways in which they interacted with their hard hats; how they wore the hard hats, carried them, personalized them, etc.

During our field visit each member on the team was given a hard hat to wear with the protective gear to better simulate what it felt like to use the product on a regular basis.

The insights generated greatly influenced our designs and helped us to connect with our clients.

Some of our primary observations were:

The lack of proper ventilation in the hard hat designs

How uncomfortable the sweat band and the fastening system was

The importance of being able to weather proof the helmet, allowing the workers to continue working no matter the climatic conditions.

It is important that workers are able to differentiate between the different kinds of workers that were present on site based off of their attire

Workers loved to use stickers to personalize their hard hats and even had functional stickers that indicated certification, regulation and safety.

We also sent out a survey to which we got responses from 188 construction workers from all over the USA. These results also confirmed our takeaways from our research.

Taking all these factors into consideration we identified the issues that needed to be addressed.

Biomimicry

Biomimicry is the design and production of materials and structures that are modeled on biological entities.

During our course of secondary research we studied the structural integrity of the hard hats. We drew inspiration from the beaks of Toucans and woodpeckers, and the shells of tortoises and mantis shrimps. We even applied the basic principles of a golf ball’s structure into our design ideas. Using the multiple layers, with an in cased buffer layer to absorb impact.

We were able to conclude that Clayco takes pride in creating safe and inclusive work environments for their employees. Our insights and key learnings from our research helped to create a framework that paved a path for us to develop the future of hard hats.

Ideation + Development

Based on the learnings from our research, we created a design framework and conducted 3 rounds of sketches and ideation.

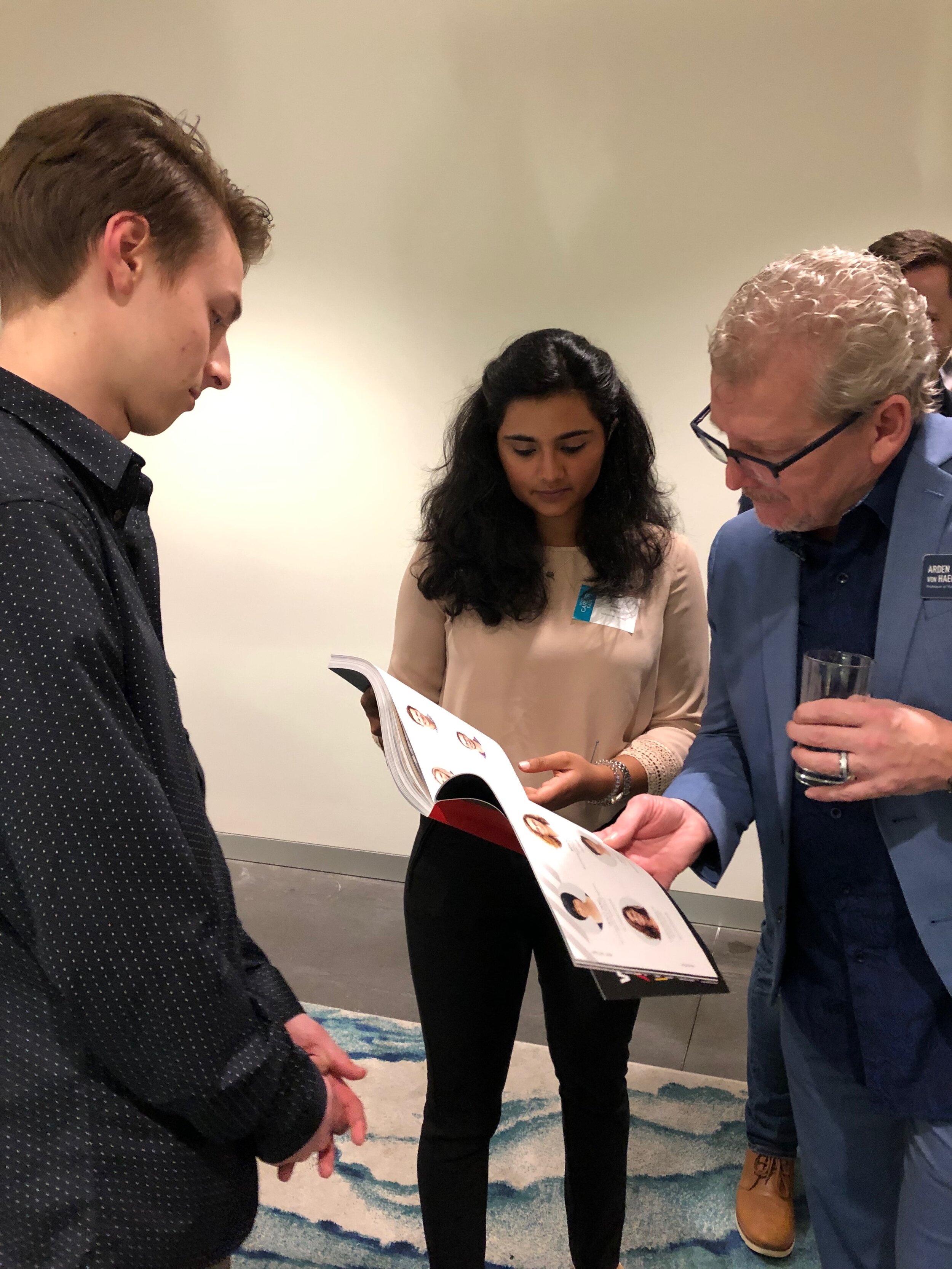

We presented 8 Hard Hat concepts to Clayco. We had an interactive feedback session with the team of clients. We ultimately landed on the decision to design 3 final concepts targeted towards 3 different user groups.

The following weeks included drawing spec sheets, 3D CAD models, 3D printing as well as creating physical prototypes to best communicate our concepts.

These are the concepts that were presented to the Clayco team at the midpoint presentation.

Final Deliverables

Attachments and Adjustability Systems

A dual port attachment system that accommodated more than one attachment at a time

A magnetic buckle is an easy one handed mechanism to simplify the chin strap interaction

Retractable ear protection enables the wearer to retract the strings on a compact spool to stow away the ear plugs.

‘Prespo’ System is an ergonomic system that adjusts to the curvature of the head through cables running from the knob to the forehead.

The Captain

The Heavy Duty Hard Hat

Captain is a compact design with improved ventilation that stays close to the head while providing comfort. The Captain also sports a dual port system. To evolve the industry further, there needed to be a way to attach multiple accessories on a single port. This system can fit two different interchangeable accessories that can pivot independently of each other. It is an intuitive system that can be removed from the hard hat when you don’t need it. The extended brim in both the front and back offer protection from the elements throughout the day.

Features:

Fixed dual-port system

Built in lights

Sturdy structure

Extended back brim for neck protection

Improved vents for airflow

Pollux

The Executive Worker’s Hard Hat

The Pollux is a full brim design which includes enhanced, closable ventilation with intakes in the front of the helmet and outlets in the back. The hard hat is equipped with a rechargeable front light on the brim and an informational sticker on the back. The design is also capable of being equipped with a magnetic detachable chin strap.

Features:

Easily accessible vent closure system

Secure fit due to the Prespo System

Full brim

Built in lights with replaceable batteries

Style is easy to transition into the industry

Detachable chin strap

Jupiter

The Adaptable Hard Hat

Jupiter is a highly versatile design capable of accommodating a variety of attachments to adapt itself to any situation while promoting comfort with added closable vents. The hard hat has four individual attachment ports compatible with visors, face shields, retractable ear protection, headphones, communication systems, chin straps, etc.

Features

Detachable dual-port system

Light weight

Wide front brim

Visible health information sticker

Large vents

Moving forward, Clayco is taking steps to continue developing these designs, and eventually manufacture them, following further testing and design processes, including input from manufacturers, OSHA, and other regulatory bodies.

For more details about this project please visit: